On the subject of an infection prevention, there’s little room for error and sterilisation failures can quietly undo even your finest efforts. When you lead an SPD or deal with compliance, it’s important to know how errors happen and tips on how to forestall them.

This text explains the commonest causes for sterilisation to fail, explains their results, and shares strategies to cease them earlier than sufferers are affected.

The Actual Causes Behind Sterilisation Failure

After going by means of the cycle, all the things appeared okay, but it surely didn’t work out, and one thing occurred. What precisely leads to a sterilisation failure? More often than not, it’s just a bit, simply avoidable error. We’ll take a look at probably the most ordinary points a bit extra intently.

1. Poor Load Configuration

If devices are packed too tightly, steam gained’t be capable of attain each merchandise. That is thought of one of the crucial possible causes for sterile management failure.

It has been found by means of a examine that 11% of sterilisation makes an attempt fail due to a malfunction in each kinds of sterilisers.

2. Leftover Biofilm Or Particles

Leaving a part of the cleansing earlier than sterilisation will enable filth and organisms to stay on the devices. Because of the biofilm, microbes can survive regardless of highly regarded cleansing cycles.

3. Flawed Packaging Supplies

The standard of wraps and containers can fluctuate considerably. While you use supplies that don’t match your sterilisation course of, the cycles often don’t full, which regularly results in issues in instrument sterilisation.

Based on one take a look at with VHP, roughly 76% of soil-covered surgical devices remained contaminated except they had been first correctly cleaned.

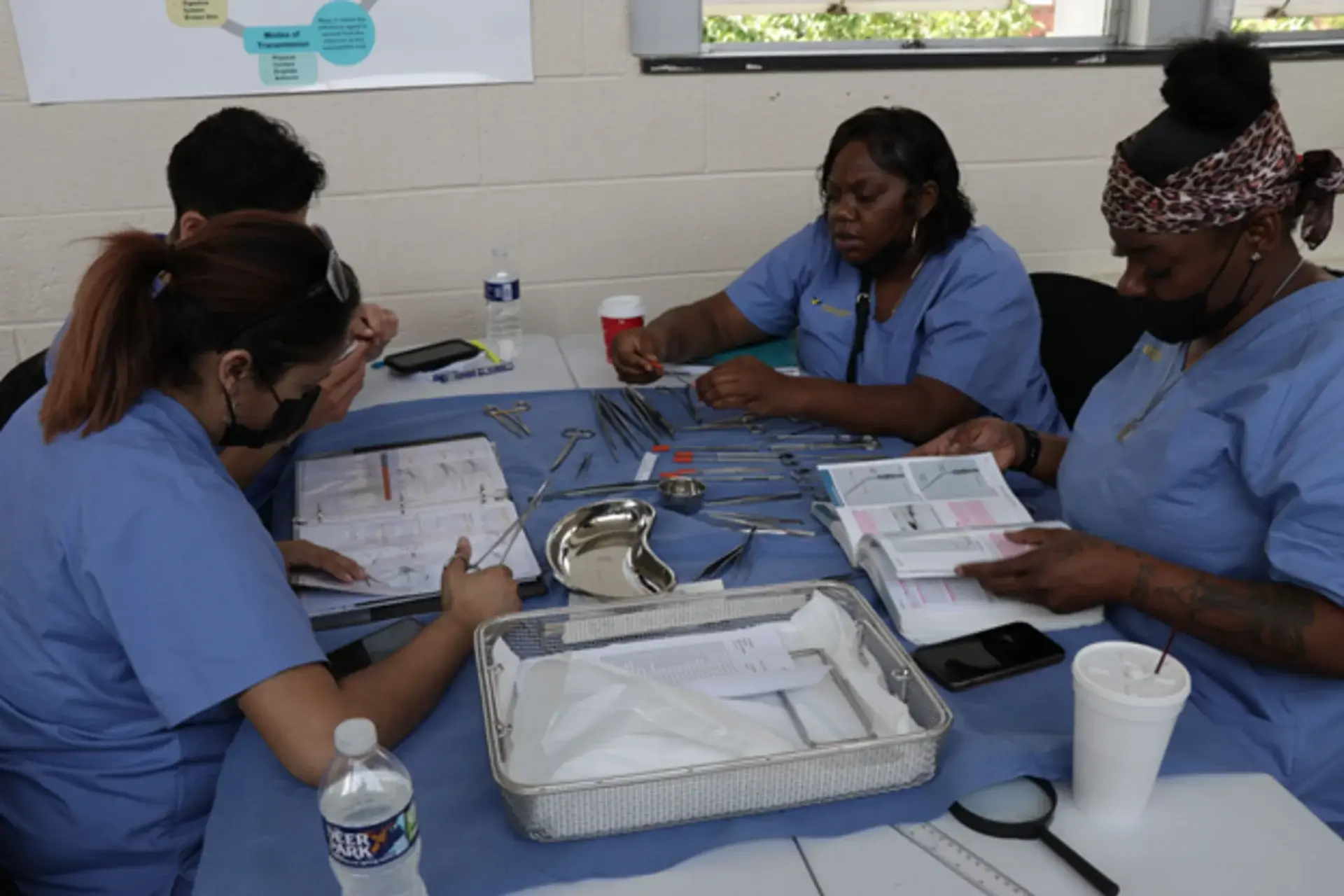

4. Operator Error

There are conditions when one thing goes unsuitable just because somebody didn’t observe the directions accurately, positioned the garments within the unsuitable location, or chosen the wrong cycle setting. Generally, even these with in depth expertise in ethics could make errors that result in sterilisation failures.

Between 2013 and 2016, 74% of “quick risk to life” (ITL) occasions reported by The Joint Fee stemmed from improperly sterilised or disinfected gear.

3 Expensive SPD Sterilisation Errors You Can Keep away from Right this moment

Sterile processing focuses on the significance of each element. Even a small mistake can result in contaminated instruments, adversarial affected person outcomes, and regulatory infractions.

Listed below are three issues with SPD sterilisation you could repair straight away.

Focused steps at a hospital diminished the variety of errors in sterilising surgical procedure devices from 3 per 100 circumstances to 1.5.

1. Ignoring Organic and Chemical Indicators

They provide knowledge to test if every step of sterilisation was carried out accurately. Not taking a look at them or misjudging the outcomes may be probably the most easy method for SPD errors to occur.

2. Outdated Documentation Practices

If documentation of the cycle logs and upkeep of kit, together with validation logs, is ignored, each protocols and monitoring of sterilisation points are additionally ignored.

3. Disregarding Up to date Tips

Operating dangers is what you do in case your requirements don’t match the present ANSI/AAMI requirements. Repeatedly checking for errors in medical insurance policies helps keep away from important issues that would happen with SPD sterilisation.

How To Troubleshoot And Repair Autoclave Failure Like A Professional

Though steam sterilisers are usually not the difficulty more often than not, when they’re, issues can get out of hand quickly.

We’ll evaluation the steps to take when the autoclave shouldn’t be functioning and tips on how to resolve the difficulty rapidly.

1. Begin With The Cycle Log

Be sure that the temperature, strain, and time are inside the required limits. This lets you decide whether or not the pc’s downside is inside or on account of a consumer error.

2. Carry out Routine Checks.

Bowie-Dick and leak checks are used to identify steam leakages and air issues. Typically, these checks allow you to discover and remedy the causes of failures earlier than something severe happens.

3. Verify Gaskets And Filters

Moist garments or devices with no new indicators of micro organism are two apparent indicators the autoclave shouldn’t be functioning accurately on account of its seals.

4. Retrain Employees On Load Setup

If sterilisation pouches are usually not used appropriately or trays are positioned incorrectly, it’s extra prone to create issues. Loading and getting ready gear correctly is an effective place to begin for many options when an issue with an autoclave arises.

What Occurs When A Sterilisation Protocol Fails?

Suppose, whereas working, you discover a load that hasn’t been processed accurately. Now what? Sterilisation protocols should at all times be used appropriately, as failing to take action can result in an emergency that requires a right away and organised response.

Right here’s what occurs when a sterilisation protocol fails.

1. Quarantine The Load Instantly

Separate the units with the problems and provides them appropriate labels. Prevention of unintended use is essential for decreasing the chance of illness unfold.

2. Notify An infection Management

It’s important to inform the an infection management division if a failed sterilisation protocol occurs, and infrequently, an incident should be recorded and the chance assessed.

3. Start A Root Trigger Evaluation (RCA)

Research the logs, analyse their gear, monitor your crew’s behaviour, and look at the cycle knowledge. It’s important to determine the reason for the issue utilizing RCA, as the difficulty could also be on account of a malfunctioning autoclave, human error, or a defective piece of kit.

4. Conduct Workforce-Huge Retraining

When it seems that the procedures had been defective, retraining turns into very important. Addressing the explanations for sterilisation failure improves the probabilities of avoiding additional failures.

Conclusion

Some sterilisation failures don’t grow to be obvious till they flip into issues within the information. Nonetheless, the intense aspect is that almost all of those failures are avoidable. Minor changes, corresponding to correcting errors throughout sterilisation or repairing autoclaves, can improve security in each process. Determine your weaknesses, deal with issues promptly, and persistently adhere to the prescribed pointers. Since excellence issues significantly in sterile processing, it’s a matter of preserving lives.

Learn Extra: